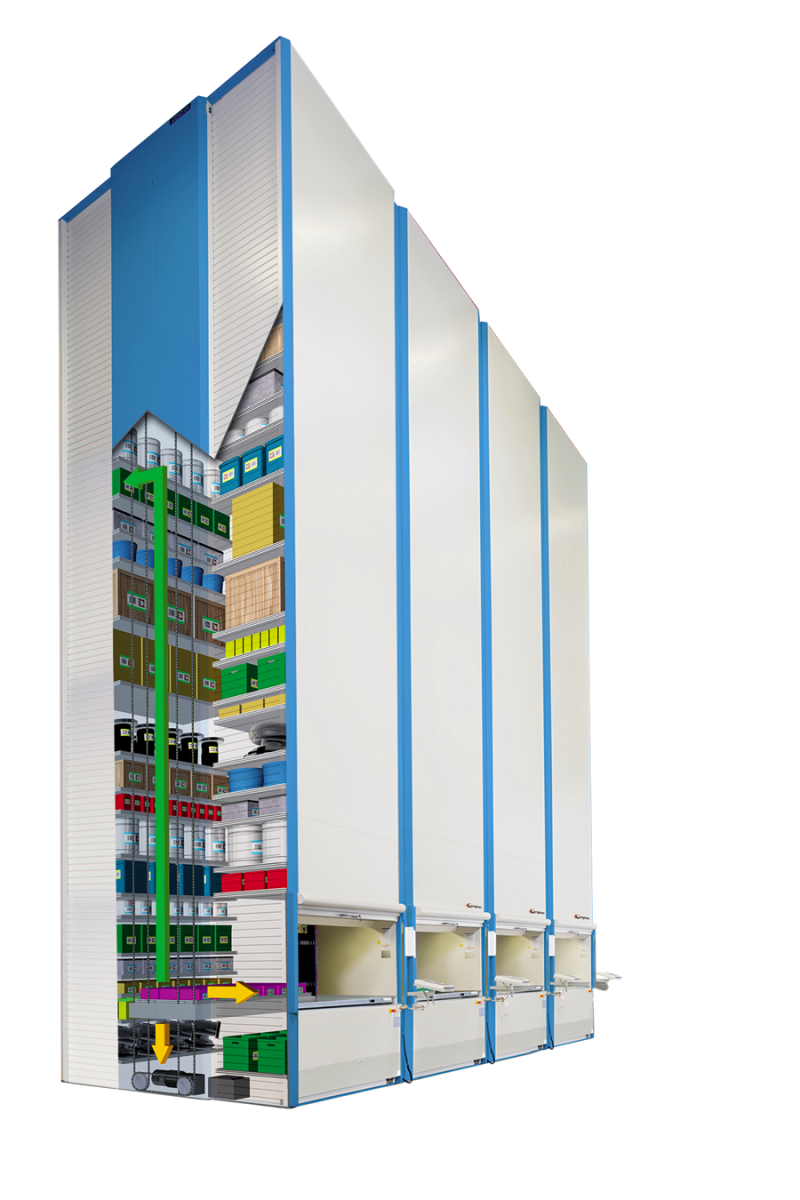

Closed automatic storage system uses trays to vertically load both sides, with the tray extractor in the middle. Through WMS storage software, realize goods warehousing and automatic data entry at the access port. Due to its ability to automatically measure the height of stored goods and achieve 25 mm vertical placement density, it is suitable for flexible storage of goods of different heights, minimizing floor space, and maximizing vertical space utilization.

Maximize vertical space utilization: Achieve a maximum vertical layer spacing of 25mm for goods, and automatically arrange storage locations based on changes of the goods on the tray.

Maximize adapt to the building: The length, width, and height can be customized, and can be designed using the maximum effective height of the building;

Floor crossing function: Multiple access ports can be designed for multiple floors to achieve shared storage space between floors and independent access for each floor;

Outdoor installation: When indoor space is limited, outdoor installation and indoor access are used to expand the storage area space.

Storage environment control: ESD protection, temperature and humidity control, nitrogen charging protection, and etc.;

Joint cabinet applications: Joint cabinet applications can be customized to further reduce equipment costs;

Software customization: Due to the differentiated management of operational requirements and material properties of our users, we provide customization services for software to maximize the adaptation to customer actual needs.

Software system docking: In addition to interfacing with primary and secondary systems such as ERP, MES, and SAP, we can achieve docking and collaborative operations with collaborative devices such as AGVs, manipulators, and conveyor lines.

Appearance spray customization: To adapt to the visual consistency of the user's factory area, we provide appearance spray customization services.

Cheap extended warranty service: To minimize user’s maintenance costs, we provide cost-effective warranty extension services.

Complete safety protection: tray overload protection, cargo out-of-tolerance protection, extractor tilt monitoring, operation port safety light curtain, anti impact top protection, anti pier bottom protection, circuit protection, automatic fault self-diagnosis and other safety protection.

Rich optional configurations: built-in/external safety doors, console height customization, single/dual tray extraction, console internal/external, automatic/manual tray extraction, visual panel, future relocation design, future height increase reservation design

Rich selection of auxiliary functions: electronic cargo location labels, laser cargo location indications, mobile operating terminals, PDA sorting, barcode equipment sorting, camera monitoring records, high-precision weighing and metering, tray physical zoning, tool handle brackets, special item brackets, transfer trolleys, sorting and seeding racks, lifting equipment, etc