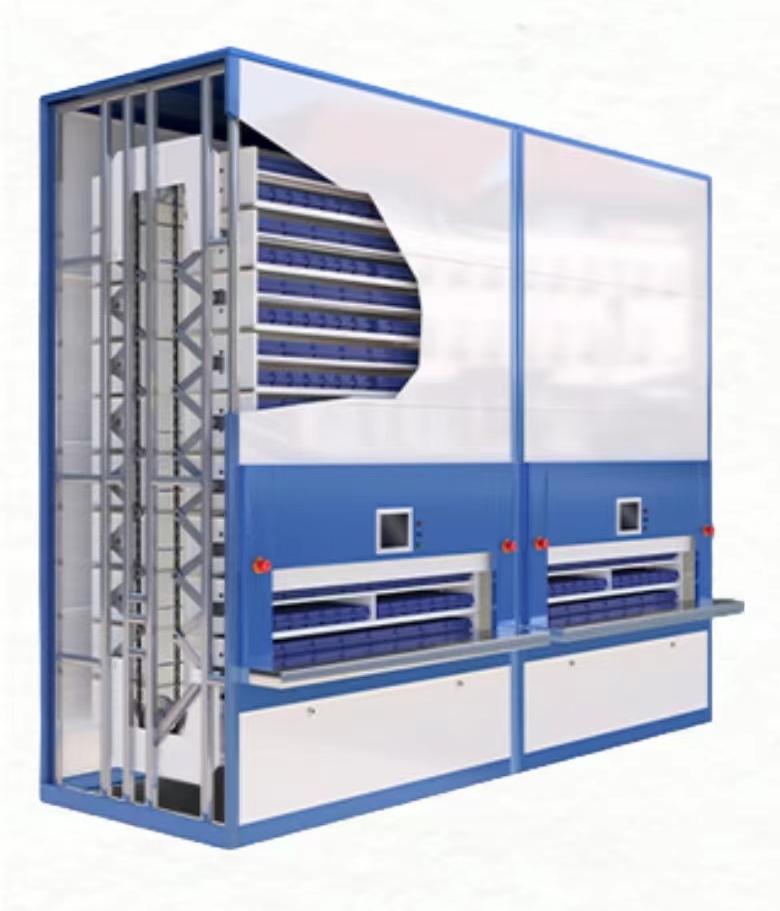

The closed automatic storage system uses the Ferris rotation principle to achieve automatic arrival of the storage hopper at the access port through chain bucket rotation, and can automatically select the shortest path through optimization algorithms to achieve rapid picking. Therefore, it is particularly suitable for use environments with high frequency storage, achieving maximum storage capacity with minimum floor space.

Maximize adapt to the building: The length, width, and height can be customized as needed, and can be designed using the maximum effective height of the building, with a maximum height of up to 10m;

Floor crossing function: Multiple access ports can be designed for multiple floors to achieve shared storage space between floors and independent access for a single floor;

Outdoor installation: When indoor space is limited, outdoor installation and indoor access are used to expand the storage area space.

Storage environment control: ESD protection, temperature and humidity control, nitrogen charging protection, and other functions can be customized;

Software customization: Due to the differentiated management of operational requirements and material properties of our users, we provide customization services for warehousing software to maximize the adaptation to customer actual needs.

Software system docking: In addition to interfacing with primary and secondary systems such as ERP, MES, and SAP, we can also achieve docking and collaborative operations with collaborative devices such as AGVs, manipulators, and conveyor lines.

Appearance spray customization: To adapt to the visual consistency of the user's factory area, we provide appearance spray customization services.

Cheap extended warranty service: To minimize user maintenance costs, we provide cost-effective warranty extension services.

Complete safety protection: operation port safety light curtain, partial load protection, circuit protection, automatic fault self-diagnosis and other safety protection, emergency manual operation.

Abundant optional configurations: height customization of the operating platform, personalized partition/partition of the hopper, secure drawer type storage, secure discrete door control, future relocation design, etc.

Rich selection of auxiliary functions: electronic cargo location tags, mobile operating terminals, PDA sorting, barcode equipment sorting, automatic warehousing and transfer, camera monitoring and recording, high-precision weighing and metering, transfer trolley, etc.