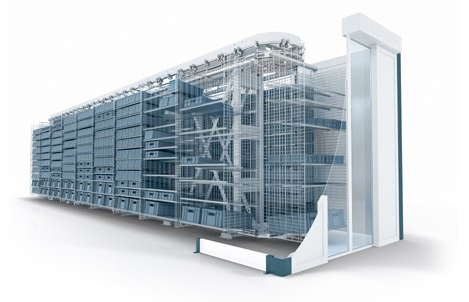

Compared to other types of storage systems, horizontal rotating containers achieved the characteristics of "fast response, large throughput, and short delivery cycle." Following the principle of "goods to people", directly transport the required items to the picking port using the shortest path. Especially for goods with large daily throughput, they can maximize the storage requirements of first in, first out, rapid warehousing, and order consolidation batch operations, Promote the picking efficiency to a higher level.

Applicable environment: warehouses with a relatively low height, generally below 4.5m, are most suitable

Suitable for goods: The shelf compartment can be adjusted as needed to accommodate goods of different heights and the most dense placement

Bracket load: 500kg/750kg/1000kg

Bracket height: 1800~4000mm, optionally customized

Bracket width/depth: customized as needed

Carrier compartment load: ≤ 100kg

Slewing length: 3600~60000 mm

Rotation speed: 20m/min

Picking ports number: customized as needed, single station or multiple stations

Peripheral protection: Fence/enclosure is a shield/glass shield

Software Customization: Due to the differentiated management of our users in terms of operational requirements and material properties, we provide customization services for warehousing software to maximize the adaptation to customers' actual needs.

Software system docking: In addition to interfacing with primary and secondary systems such as ERP, MES, and SAP, we can also achieve docking and collaborative operations with collaborative devices such as AGVs, manipulators, and conveyor lines.

Appearance spray customization: To adapt to the visual consistency of the user's factory area, we provide appearance spray customization services.

Cheap extended warranty: To minimize user maintenance costs, we provide cost-effective warranty extension services.

Complete safety protection: automatic safety door, cargo out-of-tolerance protection, operation port safety light curtain, circuit protection, automatic fault self-diagnosis and other safety protection.

Rich selection of auxiliary functions: electronic cargo location labels, physical sorting buttons, touch operated terminals, PDA sorting, barcode equipment sorting, camera monitoring records, high-precision weighing and metering, transfer carts, sorting and seeding racks, etc