Implementation process: on-site communication and investigation - formulation of solutions - adjust and lock- clarification of various indicators - performance of contracts, delivery and acceptance

After sales service: The entire system is guaranteed for two years

Project value: Complete online data on purchase, sales, inventory, work in progress, and finished products, high efficiency management, and flexible operations provide managers with a data flow foundation for remote management, greatly contributing to the improvement of corporate image, lean management, and competitiveness of the enterprise.

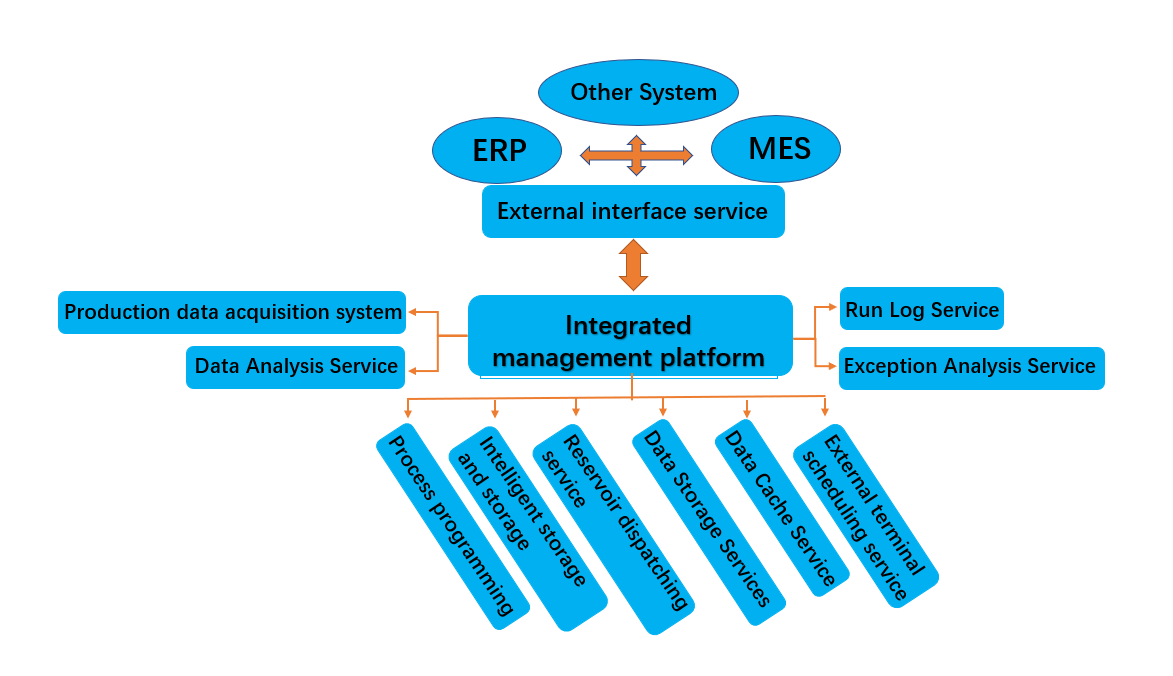

Complete system platform: integrated warehouse management platform+warehouse scheduling software+client software

Management improvement: intelligentize material management and substantially promote lean management

Image improvement: Operators with fixed positions and perform quantitative work, the site is clean, leading time is significantly reduced, and the overall quality of the enterprise is improved

One-to-one management: one-to-one warehousing management for trays, boxes, standard packaging, etc

Anti fooling and error proofing: manual non thinking operations, system anti fooling and error proofing

Automatic height measurement: arrange storage positions according to the actual height of the goods, with vertical cargo spacing less than 15mm

Extraction speed: up to 8s/SKU

Cache function: optional cache area function to further improve the efficiency of inbound /outbound

Inbound/outbound: Respond to work order batches, one-to-one sequential issue, unique code management, dynamically define addresses, and support RFID dynamic management

Software management: real-time inventory, material shortage warning, hierarchical permission management, first in, first out, split priority, expiration date management

Software docking: comprehensive docking with ERP, MES, WMS, etc

Environmental control: temperature and humidity management, nitrogen charging management, electrostatic elimination

Safety protection: safety door, safety grating, anti pinch design, multiple electrical and mechanical interlock protection

Single /online: it can be used for single machine operation or multiple machine linkage operation

Automated logistics: Seamless docking with automatic logistics equipment to achieve automatic picking and distribution

Material type: light, medium to small size, multiple matching schemes

Applicable venue: Height less than 8 meters, not suitable for traditional three-dimensional storage

Applicable materials:

Entry and exit methods: whole deposit and withdrawal, whole deposit and zero withdrawal

Material type: light, medium to small size, multiple matching schemes

Equipment length, width, and height: customized according to the actual site, with a length of up to 60m

Number of access ports: single station or multiple stations

Access port location: all sides of the device can be accessed

Maximum load: 500kg/tray